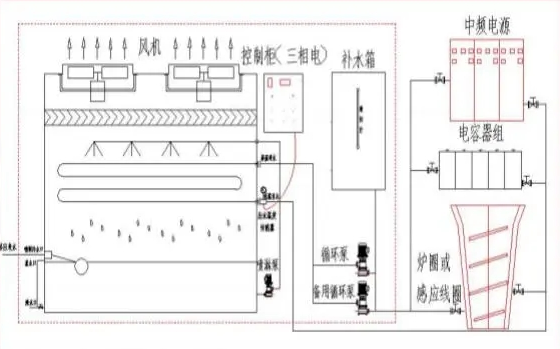

The water cooling principle of the intermediate frequency furnace is that the heat generated during the operation of the intermediate frequency furnace is cooled by the heat exchange tube bundle of the closed cooling tower to complete the closed and reciprocating cycle process. Since this circulation process is a closed loop, there is almost no loss of circulation medium.

Intermediate frequency furnace water cooling process

1. Intermediate frequency furnace cooling parts

The cooling of the cooling tower of the intermediate frequency furnace is actually the process of alternating use of circulating water cooling, so that the parts that need to be cooled can achieve the purpose of cooling by means of the evaporation and heat dissipation of the cooling tower. Make full use of the water-saving and energy-saving features of the closed cooling tower to greatly reduce the operating cost of the intermediate frequency furnace.

The intermediate frequency furnace is a kind of induction heating equipment, which can generate a lot of heat during its operation, and this part of the heat needs to be cooled. The cooling process is to take away the high temperature by cooling water.

The parts that generate heat during the overall system operation of the intermediate frequency furnace include: intermediate frequency furnace thyristors, reactance capacitors, bus bars, water-cooled cables, and intermediate frequency furnace induction coils. The most important heating components are: intermediate frequency power supply and intermediate frequency furnace coils. If the above If the heat is not dealt with in time, it will damage the core components of the intermediate frequency power supply. Therefore, the intermediate frequency furnace must be kept cool with cooling water to ensure the normal operation of the equipment.

2. The role of closed cooling tower in the cooling of intermediate frequency furnace

Closed cooling towers are widely used in the production process of intermediate frequency furnaces.

The external circulation spray water in the closed cooling tower is pumped by the spray water to the branch pipeline system, and then evenly sprayed on the heat exchange tube bundle cooler through the spray nozzle, and the internal circulation cooling medium flows outside the heat exchange tube bundle. Spray water for complete heat exchange.

In the process of this work, the internal circulation medium achieves the purpose of cooling, and the spray water reflows to the packing layer after absorbing the temperature, and then forms a uniform water film on the surface of the packing, which greatly increases the contact surface between water and air. The longer the contact time, the more fully the heat exchange between water and air.

Post time: Apr-18-2023