professional factory for Cake Chiller - Air Cooler – SPL

professional factory for Cake Chiller - Air Cooler – SPL Detail:

■ Zero Water Consumption

■ Less maintenance.

■ No Chemical Dosing required.

■ Highly corrosion-resistant material and contemporary technology that requires only periodic inspection.

■ No Scaling / Limescale deposit on the Fins / Tube.

•Material of Construction: Tubes of Copper and Aluminum fins.

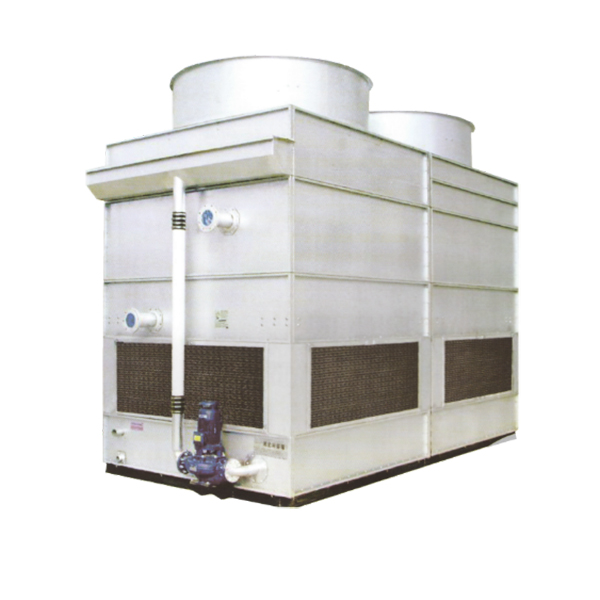

•One of the most distinctive features of our air coolers is its robustness. Designed thinking mainly in industrial applications, they must ensure optimum performance and resistance to time running and extreme working conditions.

•All components that serve as support or frame to the coil, as well as the support of the fans structure are constructed with panels or profiles of galvanized steel with thickness of 2 or 3 mm.

•The legs or feet of anchor of the whole are also built with 4 mm thick galvanized sheet profiles.

Principle of Operation: Air Cooler uses the Ambient Air to cool the Process fluid inside the coil. The Hot fluid loses its heat vide the Copper tube and the fins provided to increase the Heat Transfer Area.

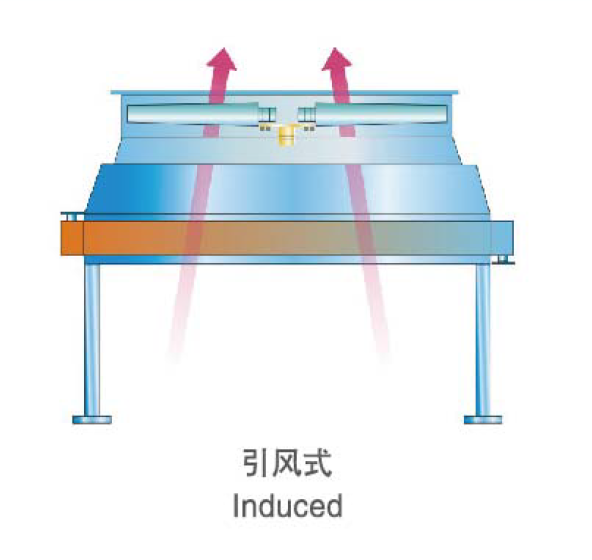

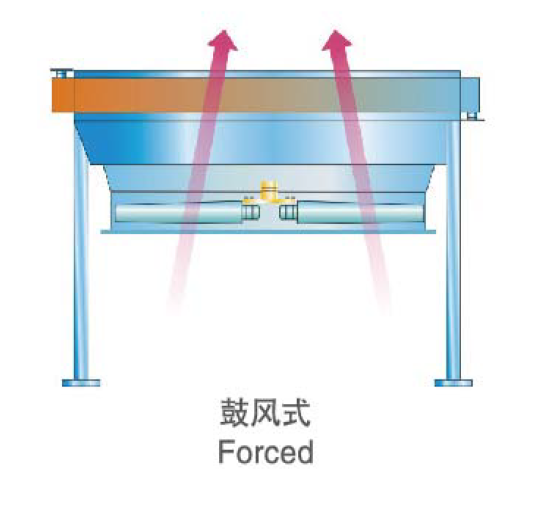

The Fans induce or force, the Ambient air over the Finned Coil bundle, which carries the heat from the fluid and dissipate in the atmosphere.

In case of Induced draft fans the tube bundle is located below the fan. The fan protects the finned tube to reduce the influence of sunlight, wind, sand, rain, snow and hail storm, so that the air-cooled appliance has stable heat transfer performance; at the same time, it can evenly distribute the air with low noise.

In case of Forced draft fans the tube bundle is located above the fans. It is suitable for high temperature process application, it is easy to clean and repair, less maintenance with low energy consumption.

Air cooler using air as cooling medium is not only a choice of low investment and low operation cost, but also choice of saving limited water resources, reducing the discharge of industrial sewage and protecting the natural environment.

| •Power | •Chemical Industry |

| •LNG | •Iron & Steel |

| •Petroleum | •Energy |

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for professional factory for Cake Chiller - Air Cooler – SPL, The product will supply to all over the world, such as: Kuwait, Cape Town, Bogota, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.