Air Cooler

■ Zero Water Consumption

■ Less maintenance.

■ No Chemical Dosing required.

■ Highly corrosion-resistant material and contemporary technology that requires only periodic inspection.

■ No Scaling / Limescale deposit on the Fins / Tube.

•Material of Construction: Tubes of Copper and Aluminum fins.

•One of the most distinctive features of our air coolers is its robustness. Designed thinking mainly in industrial applications, they must ensure optimum performance and resistance to time running and extreme working conditions.

•All components that serve as support or frame to the coil, as well as the support of the fans structure are constructed with panels or profiles of galvanized steel with thickness of 2 or 3 mm.

•The legs or feet of anchor of the whole are also built with 4 mm thick galvanized sheet profiles.

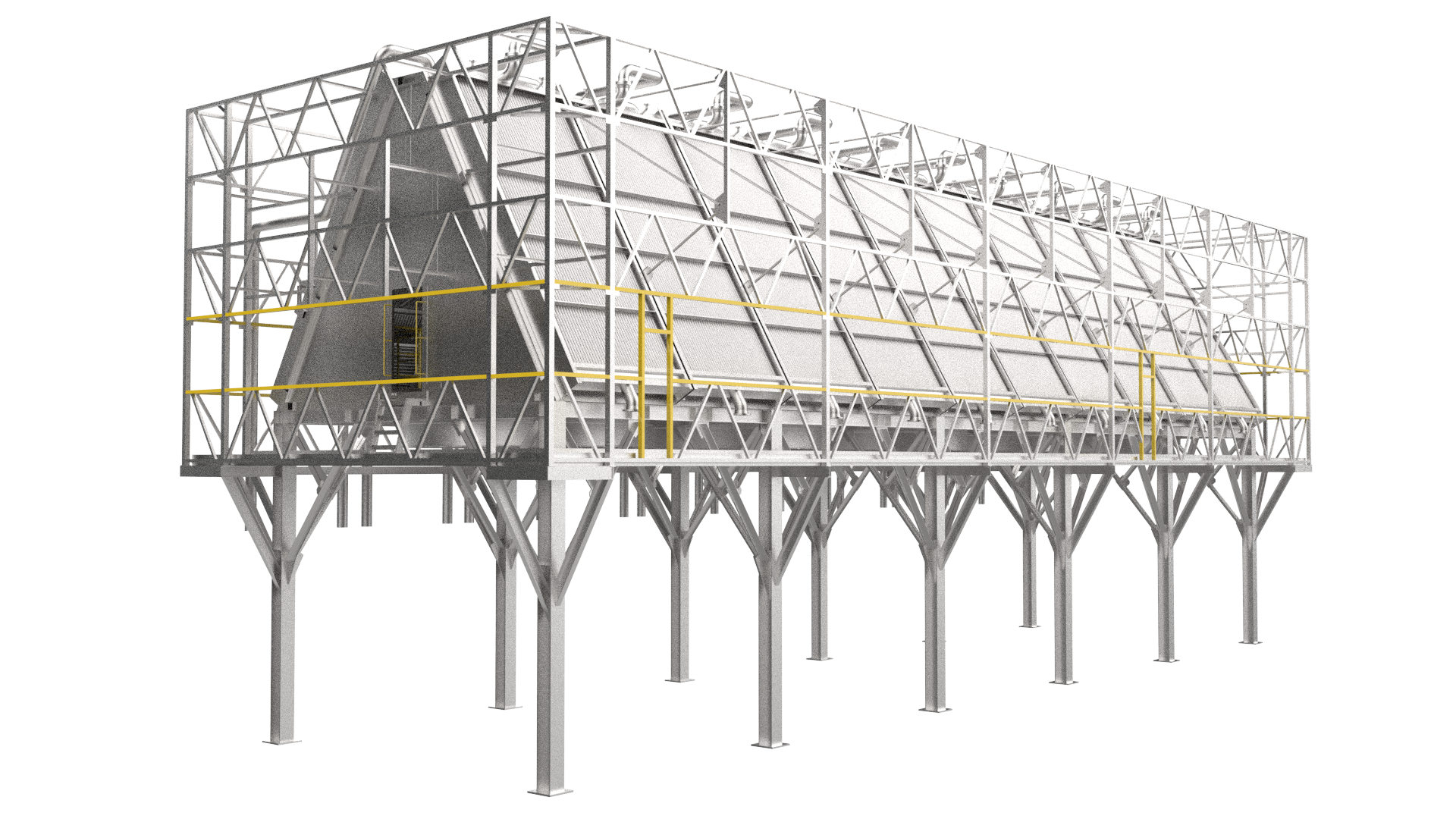

Principle of Operation:The dry-type air cooler consists of a finned tube bundle, fans, louvers, maintenance platforms, a framework, and other user-specified components. During operation, the material to be cooled flows inside the tubes while the fan drives ambient air over the external fins. Utilizing the temperature difference between the inside and outside of the tubes, as well as the enhanced heat transfer area provided by the fins, the system achieves condensation and cooling of the medium within the tubes, saving 100% of water resources in the process. This equipment, employing ambient air as the cooling medium, is widely used in chemical, petrochemical, refining, power stations, waste-to-energy plants, and steel mills.

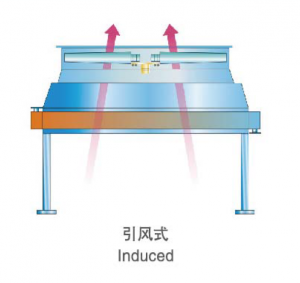

Induced draft:

The finned tube bundle is positioned below the fan and wind barrel. The wind barrel effectively protects the finned tube bundle from dust, rain, snow, and excessive sunlight, ensuring stable heat transfer performance. Additional advantages include uniform air distribution, minimal hot air recirculation, low noise levels, and a long service life.

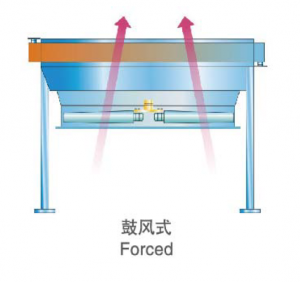

Forced draft:

The finned tube bundle is located above the fan and wind barrel, with the fan motor situated at the bottom of the air cooler. This layout offers convenient maintenance access. The motor operates in a relatively cooler environment, which significantly extends its service life.

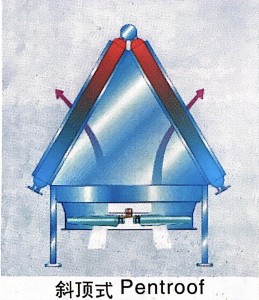

Pentroof:

The finned tube bundle is inclined at a 60° angle on top of the structure, occupying a relatively small area, which is suitable for the condensation of materials. The resistance drop inside the tubes and the heat transfer coefficient are superior to those of horizontally mounted air coolers.

Air cooler using air as cooling medium is not only a choice of low investment and low operation cost, but also choice of saving limited water resources, reducing the discharge of industrial sewage and protecting the natural environment.

| •Power | •Chemical Industry |

| •LNG | •Iron & Steel |

| •Petroleum | •Energy |